|

1 2 3 4 5 6 7 8

PU Air Filters Line

Cartridge Oil Filter Workshop

Cabin Filter Production Line

Glue Machine

Welding Machine

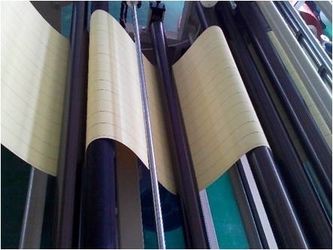

Pleated Media Machine

Slitting Machine

PU injection

|

PU Air Filters Line Automatic conveyor line with multi-station to ensure the high efficiency. |

Cartridge Oil Filter Workshop Ecological oil filters are fast becoming a significant percentage of oil filter applications. IFILTER has been a leader in developing a full range of "eco-style" filters from the smallest applications to the largest over the road diesel truck applications. |

Cabin Filter Production Line IFILTER has the most comprehensive range of cabin air filters. We have a clean workshop to prevent the contamination from the dust and keep the good quality. |

Glue Machine Auto Glue Machine with multi-station have high efficiency |

Welding Machine Auto welding Machine with multi-station have high efficiency and production output. |

Pleated Media Machine We can make the different pleated height according to product dimension. |

Slitting Machine The slitting dimension is made according to the product height |

PU injection The PU volume and proportion is automatically controlled by the machine to maintain the stable quality. |

|

1 2 3 4

Process Flow Chart

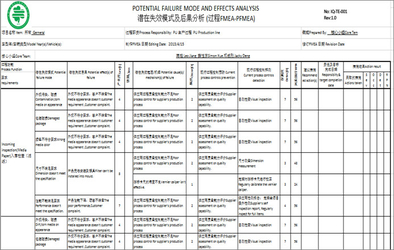

Process PFMEA

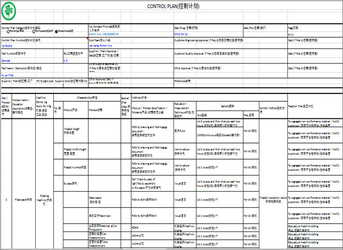

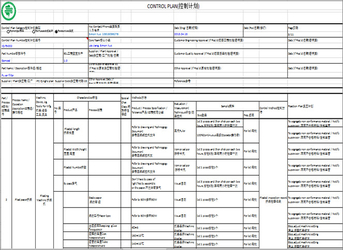

Process Control Plan

Process WI

|

Process Flow Chart Manufacture Process Flow Chart covers the Manufacture, Transfer, Storage and Inspection. Identify the process and product characteristic. |

Process PFMEA Failure Mode and Effects Analysis. We can use software to edit the P-FMEA which can evaluate the potential technical risks of failure of a product or process,analyze the causes and effects of those failures,document preventive and detection actions,recommend actions to reduce risk,the P-FMEA documents and tracks actions that are taken to reduce risk |

Process Control Plan The purpose of this control plan methodology is to aid in the manufacture of quality products according to customer requirements. It does this by providing a structured approach for the design,selection and implementation of value-added control methods for the total system. Control plans provide a written summary description of the systems used in the minimizing process and product variation. |

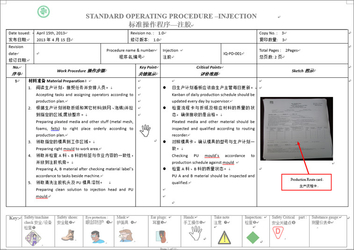

Process WI Process work instruction is a document that describe the process or activity how to operate and ensure the process stability. |

|

1 2

Cartridge Oil Filter Drawing

Spin Oil Filter Drawing

|

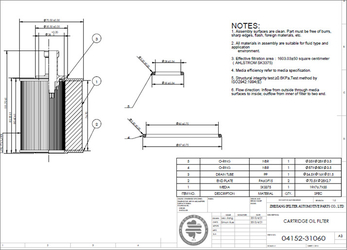

Cartridge Oil Filter Drawing The drawing is made according OE dimension. |

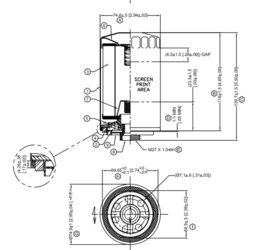

Spin Oil Filter Drawing The critical dimension is marked on the drawing. |

Product Qualtiy Planning Cycle

![]()

![]()

![]()

• We use APQP and PPAP tools to conduct the whole advanced development process.

• We apply the FMEA and DOE tools to develop and design the product.

• We can apply tthe AutoCAD systems, UG systems to make the drawings and document to the sample for customer's approval.

• We have a capabilty to fast development according the customer's requirment.

• We follow the development Process from prototype to PTR to SOP step for approval.

• The designed and developed product can be met with OE performance and fit function to vehicle.

Contact Person: Mr. Simon Xue

Tel: 13819096276

Fax: 86-0573-82581368